Polymer Design Using Machine Learning and Artificial Intelligence

Overview

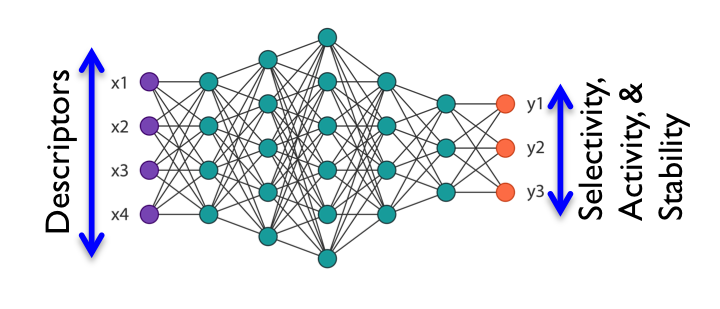

Structure-property relationship (a correlation between monomer structure descriptors and properties) studies are needed to fully realize the potential of polymeric material platform. Our goal is to create high-performance implantable biomaterials with all desired properties utilizing computer-aided material design with a machine learning algorithm and deep learning method (see Figure 1). In particular, the goals of this study are to (1) develop a computer-aided material design algorithm for advanced biomaterials development and (2) develop a versatile and high-performance zwitterionic polymeric platform with superior anti-biofilm and tunable properties with multiple parameters.

In rare experiments, when there is not enough experimental data to train the machine learning algorithm, we will generate synthetic big data. To train the machine learning algorithm using this data, and predict stress-strain relationship, we perform all-atoms molecular dynamics simulations using the setup applied in the rare experiments. For instance, we apply a uniaxial tension on a polymer network until the material breaks down as shown in Movie 1, where vertical cracks show up. We then record the stress-strain relationship to train the machine learning algorithm using various fingerprints.

Figure 1. Machine learning and artifical intelligence can be harnessed to use material descriptors, and quickly predict material properties for screening, and optimize them under certain constraints.

Movie 1. All-atom molecular dynamics simulations of 90,000 atoms representing a polymer network (top) and the correspoding stress-strain relationship as the network is uniaxially stretched (bottom).